In 1902, Voelker obtained a core patent — utilizing the heat generated by electric current passing through glass batch materials to melt glass. Subsequently, with the continuous optimization and upgrading of furnace structure design and electrode technology, this electric melting technology was widely promoted and gradually developed into the mature application technology of all-electric glass melting furnaces today.

I. Working Principle

Glass exhibits conductive properties at high temperatures, and the alkali metal ions (such as sodium and potassium) contained in molten glass are the core source of its conductivity. When electric current passes through the molten glass, it induces the Joule effect to generate heat. When the heat reaches a certain intensity, the glass raw materials can be melted. Based on this principle, the all-electric glass melting furnace is an industrial electric melting equipment specifically designed for glass melting.

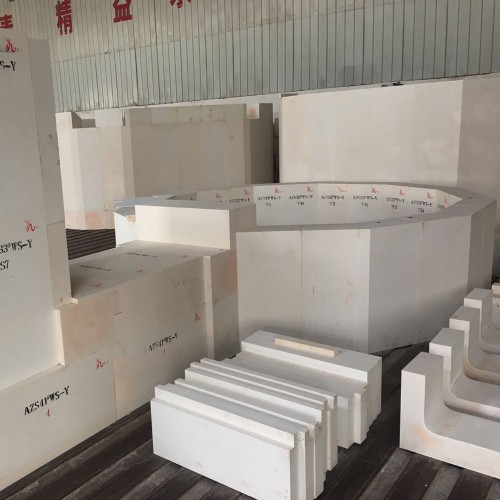

Its core components include molybdenum electrodes, heating systems, and refractory brick structures, with a thermal efficiency of 80%-85%. Modern all-electric glass melting furnaces have been further upgraded, adopting cold-top technology (with a top temperature of approximately 50℃), automatic feeding systems, and multi-layer electrode configurations. They not only can precisely control the temperature gradient and reduce fluorine volatility but also achieve a working temperature of up to 1600℃.

II. Application Scope and Core Parameters

This equipment can meet the melting requirements of various materials such as soda-lime glass, high borosilicate glass, and lead glass, with a power consumption of approximately 0.8-2.5 kilowatt-hours (kWh) per kilogram of molten glass. Currently, it has been widely applied in the production and manufacturing of optical glass, borosilicate glass, lead glass, fluoride glass, container glass, tableware glass, pharmaceutical glass, fiberglass, and special glass for the military industry.

III. Core Advantages (Compared with Traditional Flame-Heated Melting Furnaces)

- Extremely high thermal efficiency: Since molten glass is directly used as the conductive medium for the Joule effect, the thermal efficiency of electric glass melting is far superior to that of flame-heated melting furnaces. Among them, large-scale electric melting furnaces with a daily output of over 60 tons have a thermal efficiency exceeding 80%.

- Outstanding comprehensive performance: It features a simple furnace structure, small footprint, convenient operation, and stable operation. Meanwhile, it can reduce the scattering and volatilization of expensive oxides in raw materials, lower production noise, improve environmental pollution, stabilize the melting process, and enhance product quality.

Thanks to these core advantages, all-electric glass melting furnaces have been widely adopted by an increasing number of glass production enterprises.

Post time: Jan-01-2026