-

Development History and Working Principle of All-Electric Glass Melting Furnaces

In 1902, Voelker obtained a core patent — utilizing the heat generated by electric current passing through glass batch materials to melt glass. Subsequently, with the continuous optimization and upgrading of furnace structure design and electrode technology, this electric melting technology wa...Read more -

The Circular Journey of Glass Bottles

From Consumption to Rebirth: The Circular Journey of Glass Bottles After fulfilling its consumer purpose, a glass bottle still faces numerous hurdles on its “extended lifecycle” journey toward rebirth. Nevertheless, the direction toward a circular economy has become increasingly clear...Read more -

Some of the glass furnaces we manufacture

Glass is never merely a transparent material, but more of a spirit of guardianship—it preserves the preciousness of the present and undertakes the responsibility for the future. This material, which combines timeless texture with environmental protection properties, is solidifying t...Read more -

Fused zirconia corundum brick in the production and use of the process will appear the following three kinds of cracks:

1. Stress cracks: Fused zirconia corundum brick composition of zirconia has the largest proportion of zirconium oxide, there is a segregation in the casting process, the annealing process is difficult to release the stress uniformity, and cracks occur. (JC493 standard for such cracks have specifi...Read more -

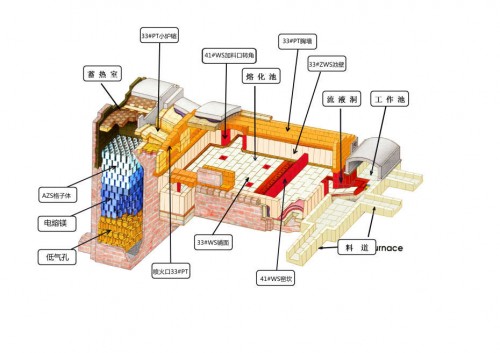

Dimensions, Specifications and Application Positions of Fused Cast AZS Bricks

Due to the temperature gradient and compositional segregation that occur during the casting of fused cast AZS bricks from melt to cooling and forming, it is difficult to uniformly release and completely eliminate the thermal stress and structural stress of the castings during the annealing proces...Read more -

Served over 1,000 glass manufacturers

As of June 2025, we have with our business covering 12 countries worldwide. We are deeply proud of this achievement, which is not only inseparable from the trust and strong support of both new and old customers, but also the result of the far-sighted leadership of the company’s management a...Read more -

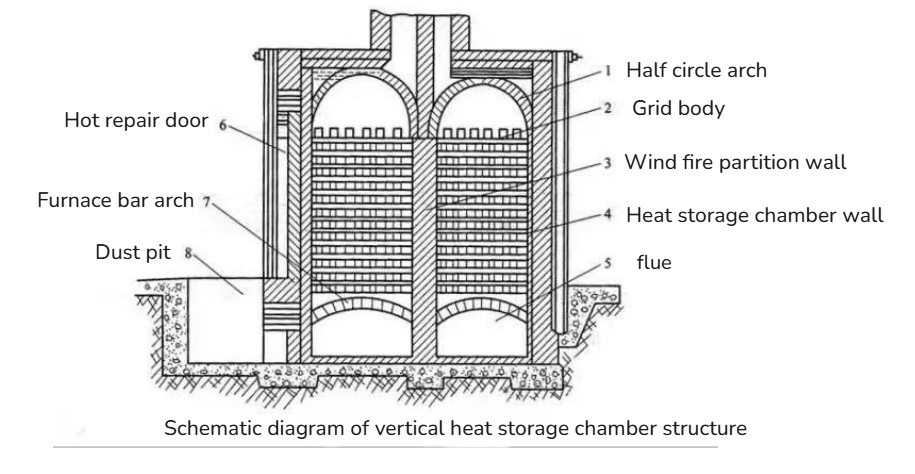

Design of the Regenerator Checkerwork in Glass Furnaces

The design of the checkerwork in the regenerative chamber of a glass furnace is a crucial aspect of the overall furnace design. A well-designed checkerwork can significantly increase the preheating temperature of the combustion air, leading to higher combustion temperatures and providing both com...Read more -

Over 30 years of experience – always one step ahead

Our journey reflects a continuous drive for product improvement and innovation, providing us with the insight, confidence and ability to keep moving forward. In our R&D department, we constantly develop new solutions for the ever-changing needs of the glass industry – thereby enhancing...Read more -

Correct production operation norms for extending the service life of the horse hoof flame pool kiln

A reasonable operation system of the melting furnace is an important guarantee for extending the service life of the melting furnace and obtaining high-quality products. The operation of the melting furnace must be carried out strictly in accordance with the sequence stipulated in the process reg...Read more -

Fused zirconium corundum

Fused zirconium corundum Electric fused zirconium corundum is commonly known as white iron brick or fused cast high corundum brick. It is the most important refractory to ensure the normal operation of the glass furnace. At present, the improvement of melting rate, extension of furnace life and ...Read more -

![[Popular science] Factors of refractory material alteration in glass tank furnace](https://www.zzgj-refractory.com/uploads/窑炉11.jpg)

[Popular science] Factors of refractory material alteration in glass tank furnace

In the process of glass melting, the interaction between refractories and molten glass at high temperature will cause corrosion damage to refractories and even defects to molten glass. In the tank kiln, the corrosion effect of the batch components on the refractory is much greater than that of th...Read more -

How to inspect the melting kiln in normal operation? How to handle exceptions?

How to inspect the normal operation of the kiln? How to deal with abnormalities? ① Inspection contents a. Whether the cooling air volume and related cooling air volume at the pool wall are normal, and whether the pool wall bricks are cracked and reddened; b. Whether there is reddening and fire tr...Read more